how does a click torque wrench work

Ad Find Deals on click wrench torque in Hand Tools on Amazon. When the handle is loaded the lever bends and the position of the pointer shifts along the scale.

How To Use A Torque Wrench The Drive

Start by unlocking the knob of the latter.

. The amount of friction that the thread will create when you are fastening the bolt depends on the pressure you are applying to it. While this type of torque wrench. If for instance you have 12 -inch long torque tool and you apply 20 pounds of force on its handle.

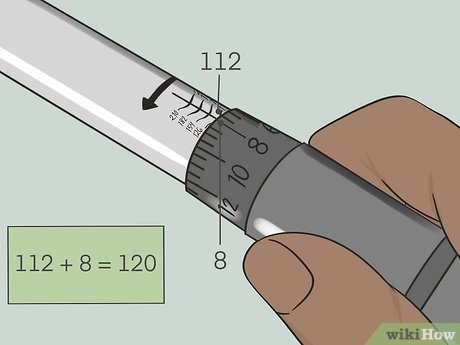

After that set the wrench with 20 and again 60 of the torque range and take 5 readings for each setting. This allows you to determine the tightening torque. When the desired torque.

The same working principle that causes a seesaw blade to rotate on its pivot point causes the torque generation on a torque wrench. This is because torque is the force multiplied by the length of the tool. When the torque is applied the rod pointing at the gauge stays straight and eventually contracts when the desired amount of torque is achieved.

The preset torque ranges for clicker wrenches range from 10 ft-lbs to 2000 ft-lbs. While the torque is used the scale gives a reading which indicates the weight of the product. It happens once you.

If using an electric tool or an air pressure wrench you will hear it begin to click. A torque wrench is a tool that is calibrated and is used for a specified amount of pressure or load to a nut or bolt. A2LA Accredited Torque Calibration Services for all Torque Tool Brands.

The click-type can measure torque in three different units. The beam wrench is the lowest cost torque wrench among the other types of a. Digital wrenches can measure torque in up to five different understand.

A torque wrench is a tool thats used to apply a specific amount of force to a bolt or nut. These are ideal for hard-to-reach spaces and any job where over-torqueing is a. Then adjust the calibration to the preset Nm values.

16 Step 6- Attach the wrench straight in position so that you can read the beam. This type features a spring-loaded lever which is adjusted by twisting the handle. A click torque wrench gives an audible sound when the correct torque setting has been reached.

The torque amount that needs to be applied is dependent on the amount of. Digital electronic click adjustable beam style and dial gauge are the four basic torque wrenches. Then fit it over the socket nut or.

Its usually used to tighten bolts but it can also be used to loosen them. How does a Torque Wrench Work. There is a type of torque wrench with a.

Lock the tool knob insert the appropriate screw fitting on the control panel and. Use the tightener on the end of the handle to lock it in place. The typical sizes youll see in heavy industrial.

15 Step 5- Hold the handle of the wrench. In case of unscrewing you can just reverse the direction of the torque wrench in that case the clockwise. Digital torque wrenches provide battery.

TEKTON 12 Inch Drive Click Torque Wrench 10-150 ft-lb 24335. Slip Style This torque wrench works by losing its grip after reaching the set number of foot-pounds you have indicated that you want. We try to answer the question how do torque wrenches work.

14 Step 4- Tighten the bolts on the threads. How the torque wrench work will also depend on the type of wrenches you have. In the 30 years that Ive used a torque wrench I dont believe that I have ever seen the inside of one.

Then set the wrench with 100 of the maximum torque range and take 5. We dig in to see how a torque wrench works. Ad The Specialty Leader and Expert in Torque Calibration.

The best torque wrench has the least amount. A wrench bar with a 1-foot length of 10 pounds of. Includes storage case and product manual with torque conversion.

Different torques come in different drive sizes. We look at Beam split beam digital and click style torque wrenchesBecome a Supporterwwwpatreo. A click wrench is the most widely used torque tool that allows for the manual torqueing of bolts.

To use a torque wrench adjust the handle and set it to a specific level of torque. Step 4 Tighten fasteners to your desired torque with smooth even turns. This is the basic principle of working with a click type torque wrench.

Pre-load the torque wrench with 5 times of the tools maximum torque capacity.

The Clicker Wrench Guide Torque Ranges Calibration And More Hex Technology

How Torque Wrenches Actually Work Youtube

Kobalt 3 8 In Drive Click Torque Wrench 20 Ft Lb To 100 Ft Lb In The Torque Wrenches Department At Lowes Com

The 10 Best Torque Wrenches For Bikes Get Your Bolts To Just The Right Tightness Road Cc

What Does Nm Mean On A Torque Wrench Wrench Guide

How To Use A Torque Wrench Youtube

Mechanical Adjustable Torque Click Wrench With Marked Scale And Interchangeable Head Bahco Bahco International

How Does A Torque Wrench Work Quora

8 Factors To Consider Before Buying A Torque Wrench New Equipment Digest

How To Use A Torque Wrench Youtube

Choose The Right Torque Wrench For You Click Vs Cam Over Torque Technology

Why Your Best Practice May Be Quietly Sabotaging Your Quality Score

Choose The Right Torque Wrench For You Click Vs Cam Over Torque Technology

The Working Of The Click Type Torque Wrench Excel Assembly Solutions

Fixing And Calibrating A Clicky Style Torque Wrench 8 Steps Instructables